We’ve all been there – trying to make a delicious cup of coffee, only to find it’s filled with sediment and grounds. Or, maybe you’re a scientist in a lab, meticulously conducting experiments, only to discover your results are compromised by contaminants. The need for effective filtration is a constant across various fields, and that’s where Gelman Sciences filters come in. Gelman Sciences, now a part of Pall Corporation, has been a leader in filtration technology for decades, providing high-quality solutions for a wide range of applications.

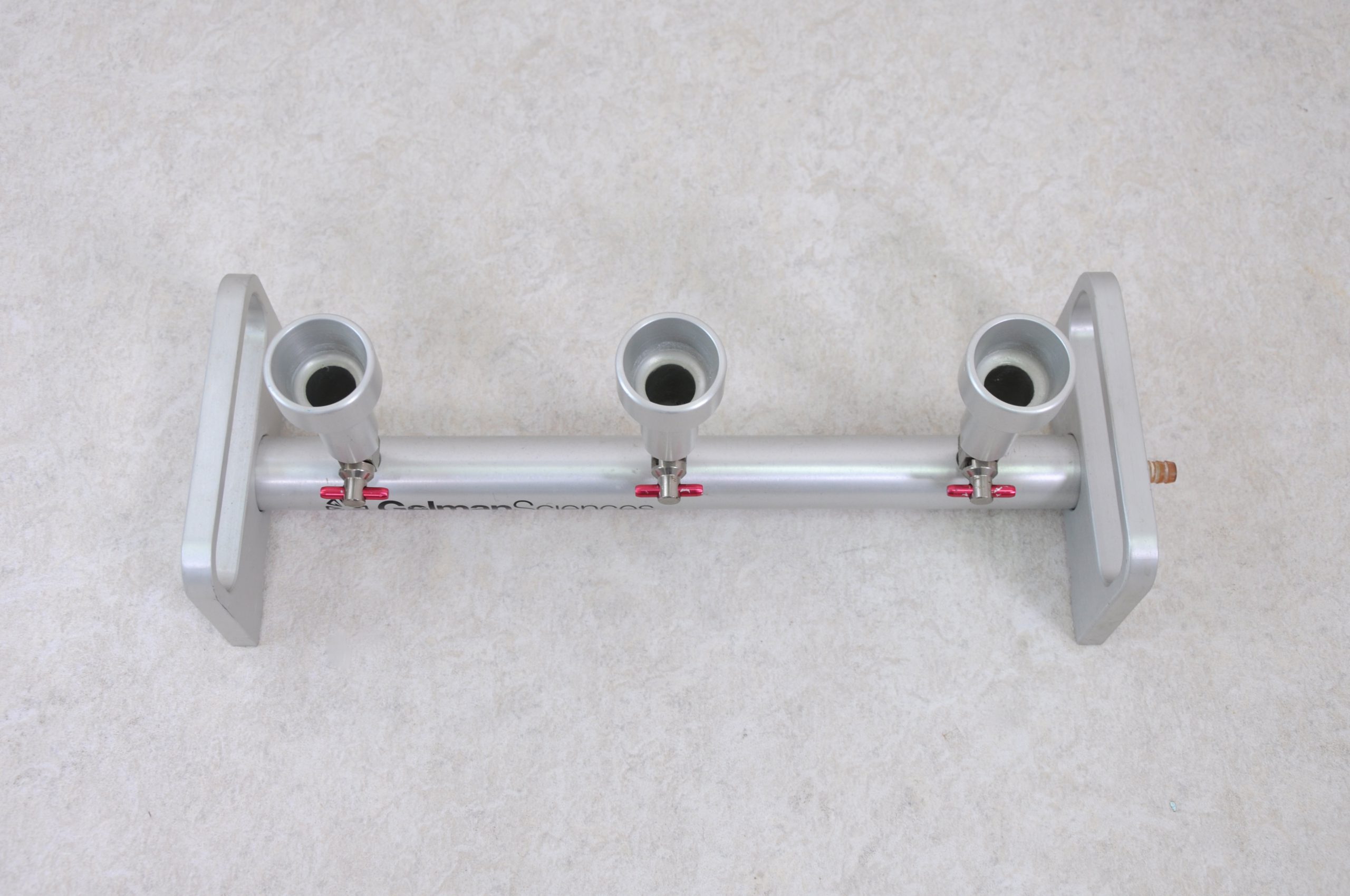

Image: www.krackeler.com

This article will delve into the world of Gelman Sciences filters, exploring their history, types, applications, and the significant role they play in diverse industries. We’ll also look at the latest trends in filtration technology and provide some expert tips on choosing the right filter for your needs.

A Legacy of Innovation: The Gelman Sciences Story

Gelman Sciences emerged in the 1950s, pioneering the use of membrane filtration techniques, which revolutionized the way we purify and analyze liquids and gases. The company quickly gained recognition for its innovative filter designs and their ability to handle a wide variety of applications, from water purification to pharmaceutical research.

One of their key breakthroughs was the development of the first disposable syringe filter, a groundbreaking innovation that made laboratory filtration more accessible and efficient. Gelman Sciences’ focus on quality and innovation led to its acquisition by Pall Corporation in 2003, a company known for its own global presence in filtration and separation technologies.

Understanding the World of Gelman Sciences Filters

Gelman Sciences filters are known for their high-quality materials and reliable performance across numerous applications. They offer a wide range of filters, each designed to address specific needs and challenges. Some of the common filter types produced under the Gelman Sciences brand include:

Membrane Filters

Membrane filters are the workhorses of the filtration industry, offering highly efficient separation of particles from liquids and gases. They are made from a variety of materials, including:

- Cellulose acetate (CA): Economical, commonly used for general filtration tasks.

- Cellulose nitrate (CN): Offers high flow rates and excellent compatibility with solvents.

- Polycarbonate (PC): Highly resistant to harsh chemicals and temperatures.

- Polyvinylidene difluoride (PVDF): Provides excellent chemical resistance and high flow rates.

Image: www.geminibv.com

Filter Papers

Gelman Sciences filter papers are designed for both qualitative and quantitative analysis. They are available in various grades, ranging from coarse to fine porosity, making them suitable for a variety of applications, such as particle analysis and air sampling.

Syringe Filters

Syringe filters are a convenient and efficient solution for laboratory filtration. They come with a variety of membrane types and pore sizes, making them suitable for sample preparation, sterilization, and removal of particulates.

Applications Across Industries: The Versatility of Gelman Sciences Filters

Given their wide range of filter types and excellent performance, Gelman Sciences filters play a crucial role in numerous industries, including:

- Pharmaceuticals: Sterilizing and clarifying pharmaceutical solutions, removing particulates from drug formulations, and ensuring product safety.

- Biotechnology: Cell culture media filtration, protein purification, and analysis of biological samples.

- Environmental monitoring: Monitoring water quality, air pollution analysis, and environmental research.

- Food and beverage: Clarifying beverages, removing particulates from food products, and improving overall food safety.

- Industrial manufacturing: Filtration of process fluids, air purification, and removal of contaminants from manufacturing processes.

Exploring the Cutting Edge: Latest Trends in Filtration Technology

The filtration technology landscape is constantly evolving, with innovations focused on improving efficiency, sustainability, and precision. Here are some of the latest trends in Gelman Sciences filters and filtration technology in general:

Nanofiltration:

Nanofiltration has become increasingly popular with its ability to remove very small particles and molecules, including viruses, bacteria, and even some dissolved salts. This technology is critical in applications like water purification and wastewater treatment.

Microfiltration:

Microfiltration is a key technology for removing larger particles, such as bacteria and yeast, from liquids. It’s commonly used in the pharmaceutical industry to sterilize solutions and in food and beverage processing for clarifying liquids.

Ultrafiltration:

Ultrafiltration is a powerful tool for separating proteins, enzymes, and other macromolecules. It’s widely used in biotechnology for purifying and concentrating biomolecules and in the pharmaceutical industry for developing drug formulations.

Expert Tips for Choosing the Right Gelman Sciences Filter

Given the wide array of options, selecting the appropriate Gelman Sciences filter for your needs can seem daunting. Here are some helpful tips from our team of experts:

- Identify your filtration needs: What type of liquid or gas are you filtering? What kind of particles or contaminants are you trying to remove?

- Consider the pore size: The pore size of the filter will determine the size of particles it can remove. Choose a pore size that is appropriate for your specific application.

- Think about the flow rate: The flow rate of the filter will influence how quickly you can filter your liquid or gas. Select a flow rate that is compatible with your equipment and process requirements.

- Evaluate compatibility: Ensure that the filter is compatible with the liquid or gas you are filtering. Consider factors like chemical resistance and temperature compatibility.

- Look for certifications: Choose filters with appropriate certifications, such as those from the FDA or other relevant authorities, to ensure quality and safety standards are met.

Choosing the Right Filter – A Deeper Dive:

Choosing the right filter is crucial for achieving accurate results and successful outcomes. Consider these key factors:

- Fluid Type and Chemistry: It’s essential to understand the properties of the fluid you are filtering. Is it acidic, alkaline, or solvent-based? The filter material must be compatible with the specific fluid.

- Particle Size: What size particles are you trying to remove? Refer to the pore size rating (PSR) of the filter. A smaller pore size will remove smaller particles, but will also have a slower flow rate.

- Flow Rate: How quickly do you need to filter your liquid? High flow rates are desirable for large volumes, but you may need to sacrifice pore size. Factors like membrane thickness, filter area, and pressure can influence flow rates.

- Filter Material: Choose the right material for your needs based on chemical resistance, compatibility, intended use, and regulatory requirements. For example, some filters may be specifically designed for sterilization while others may be optimized for removing specific contaminants.

- Filter Performance: Consider the quality of the filter. Look for certifications indicating adherence to industry standards and reliability. Factors like long-term performance, consistency, and ability to maintain purity are crucial.

Gelman Sciences offers a vast selection of filters, and their expertise in filtration technology enables them to provide customized solutions that meet specific needs. Contact their team to get advice and recommendations based on your unique application.

FAQ’s: Common Questions About Gelman Sciences Filters

Q1: What is the difference between a membrane filter and a filter paper?

A: Membrane filters are typically made from thin, porous materials with a uniform pore size, while filter papers are made from a fibrous material with varying pore sizes. Membrane filters offer greater precision in particle separation and are often used for sterilization and analysis, while filter papers are more suited for general filtration tasks and qualitative analysis.

Q2: How do I choose the right pore size for my Gelman Sciences filter?

A: The pore size of a filter determines the size of particles it can remove. To choose the right pore size, you need to consider what you are trying to filter out. If you are trying to remove bacteria and other microorganisms, you will need a filter with a pore size of 0.22 micrometers or smaller. If you are trying to remove larger particles, you can use a filter with a larger pore size.

Q3: What is the difference between a Gelman Sciences filter and a Whatman filter?

A: Both Gelman Sciences and Whatman are well-known brands in the filtration industry. They offer a similar range of filter types and applications, but each brand may excel in specific areas. It’s best to compare the specific filters you need based on your application requirements.

Gelman Sciences Filters

Summary & Call to Action

From their innovative beginnings to their current position as a leading provider of filtration solutions, Gelman Sciences filters continue to make a significant impact on numerous industries. Their diverse range of filters, along with the ongoing development of cutting-edge filtration technologies, ensure optimal performance and quality across a wide spectrum of applications.

If you are looking for high-quality filters that meet your needs, whether in a laboratory setting or for industrial processes, Gelman Sciences filters should be at the top of your list. Explore their website to learn more about their products and find the right filtration solution for your specific requirements.

Are you interested in learning more about the specific advantages of Gelman Science filters for your industry? Let us know in the comments below! We’re happy to discuss your filtration needs!