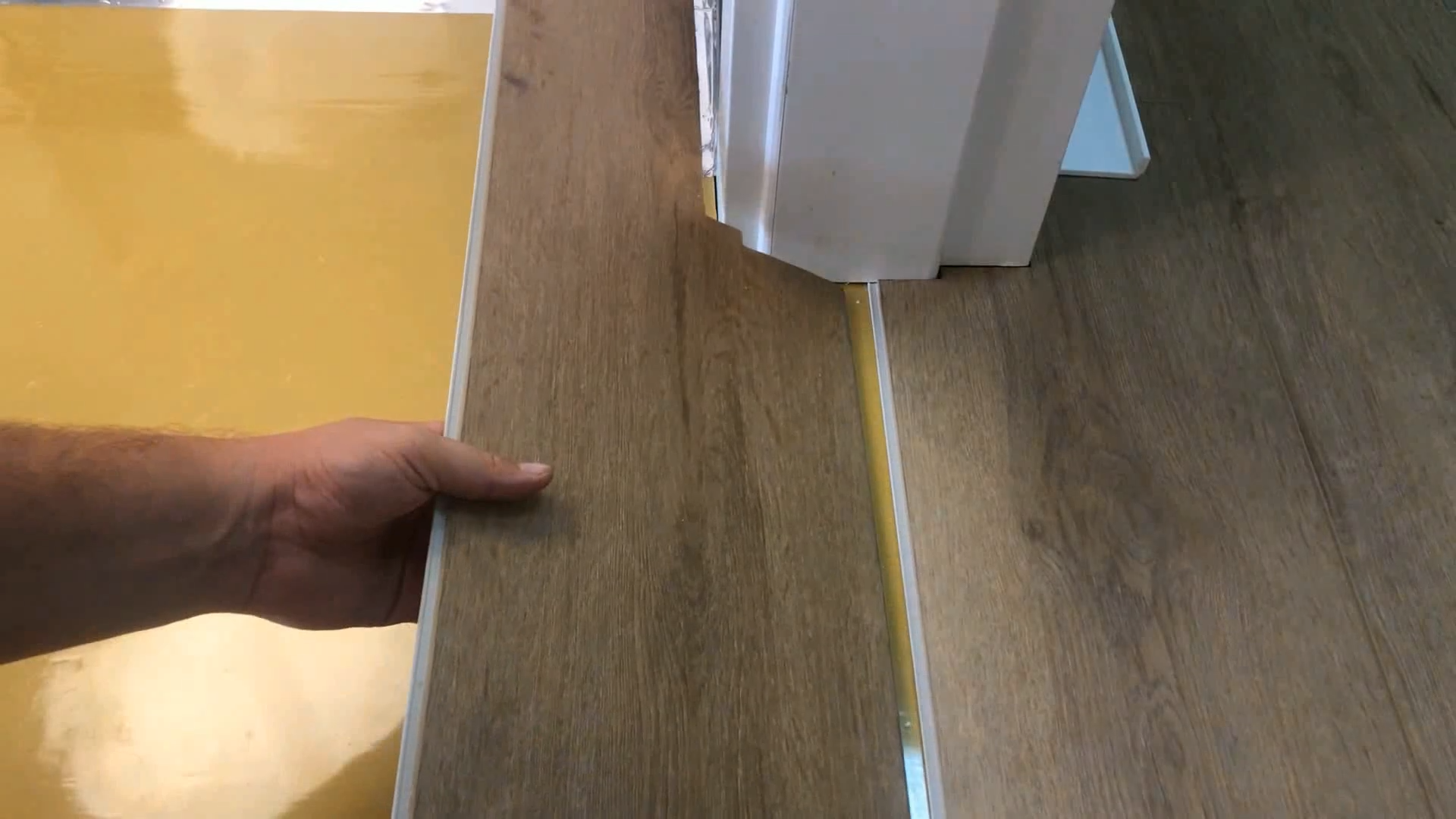

Remember that time you tried to install vinyl plank flooring only to find out your old utility knife wasn’t up to the task? The frustrating, jagged cuts and the splintered edges that took forever to clean up? That’s a story many of us can relate to. Cutting vinyl plank flooring is a common DIY project, but it requires a dedicated tool for a professional-looking finish. The right tool can make all the difference, and that’s what we’ll be exploring in this guide.

Image: viewfloor.co

From a simple utility knife to a specialized vinyl flooring cutter, there’s a wide range of tools available. But which one is the best for your needs? We’ll analyze the pros and cons of each option, compare their features, and provide expert tips to help you choose the perfect tool for your next vinyl plank flooring project.

Understanding the Importance of the Right Cutting Tool

Cutting vinyl plank flooring isn’t as simple as it seems. It requires precision and accuracy to achieve straight, clean cuts that blend seamlessly with the rest of the flooring. This is where the right tool becomes crucial. A faulty tool can lead to uneven cuts, damaged planks, and a messy installation overall. Not only will this detract from the aesthetics of your project, but it can also lead to future problems like buckling or warping of the flooring.

The choice of cutting tool often depends on your project size, the specific type of vinyl plank flooring, and your experience level. A simple utility knife might work for small cuts and trimming, but for larger projects, investing in a dedicated flooring cutter is often the better option. We’ll delve into the specifics of each type of tool to help you make an informed decision.

The Tools of the Trade: A Comprehensive Review

1. Utility Knife: The Essential Beginner

It’s the go-to tool for many DIY enthusiasts, and often the first thing people grab when they need to cut vinyl plank flooring. Utility knives are simple, affordable, and versatile, making them ideal for small cuts and trimming around obstacles. However, they can be challenging to use for longer, straight cuts due to the manual pressure required and potential for slipping, leading to uneven cuts.

Image: coretecfloors.art

Pros:

- Affordable: Utility knives are readily available and inexpensive.

- Versatility: They can be used for various cutting tasks around the home.

- Lightweight and easy to handle: Ideal for precise but small cuts.

Cons:

- Potential for uneven cuts: Requires consistent pressure and a steady hand.

- Limited for larger projects: Not ideal for long, straight cuts.

- Requires frequent blade changes: The blade can dull quickly.

2. Vinyl Plank Flooring Cutter: A Professional Advantage

When precision and speed are paramount, a dedicated vinyl plank flooring cutter reigns supreme. These cutters are specifically designed for cutting vinyl plank flooring, featuring features like adjustable cutting depths, guides, and built-in safety guards. They typically use a sharp blade to cleanly cut through the vinyl, minimizing chipping and splintering.

Pros:

- Precision and accuracy: Ensures clean, straight cuts every time.

- Efficiency: Significantly faster than using a utility knife.

- Safety features: Minimizes the risk of accidents.

- Durable and long-lasting: Built to withstand heavy use.

Cons:

- Higher upfront cost: More expensive than a basic utility knife.

- Less versatile: Designed specifically for vinyl plank flooring.

- Storage requirement: Can be bulkier than a utility knife.

3. Circular Saw: Power and Precision

For larger jobs and cuts exceeding the capability of a traditional flooring cutter, a circular saw is often the preferred solution. It’s a powerful tool with a rotating blade, allowing for quick and precise cuts through thick vinyl plank flooring. However, it requires significant skill and experience to use effectively, and safety precautions should always be prioritized when working with a circular saw.

Pros:

- High speed and efficiency: Cuts through flooring materials quickly and efficiently.

- Versatility: Can be used for various cutting tasks, including other materials.

- Powerful: Ideal for thick or multiple planks.

Cons:

- Requires skill and experience: Correct use is crucial for safe operation.

- Safety concerns: Risk of kickback and other injuries.

- Noise and dust: Operation can be noisy and create dust.

4. Table Saw: For Professionals and Large Projects

The table saw is often reserved for professional installers and those tackling large-scale projects. It involves a powerful saw blade mounted below a table, offering precise, consistent cuts with minimal effort for the user. However, this tool takes up considerable space and requires a safe and secure setup, making it less suitable for occasional home DIY projects.

Pros:

- Ultimate accuracy and precision: Delivers perfect cuts every time.

- High-speed operation: Efficiently cuts through multiple planks.

- Various adjustments: Offers numerous settings for different cuts and materials.

Cons:

- Expensive investment: Requires a significant financial outlay.

- Large footprint: Requires substantial space for setup.

- Safety requirements: Requires a dedicated workspace and safety training.

Tips and Expert Advice

No matter which tool you choose, remember these essential tips to guarantee success:

- Practice on scrap pieces first: Get a feel for the tool and its cutting action before working on your actual flooring.

- Use a straight edge or ruler: Ensure accurate cuts by guiding the tool along a straight edge.

- Cut with the grain: Always cut vinyl plank flooring with the grain (the direction of the wood fibers) to avoid splintering.

- Maintain your tools: Keep your blades sharp and lubricated to prevent them from dulling or overheating.

- Wear safety gear: Always wear appropriate safety glasses, gloves, and a dust mask to protect yourself.

Choosing the right tool for your project can make all the difference. Don’t compromise on quality for the sake of cost. Invest in a tool that will perform well and last for many projects to come. Remember, a good tool is an investment in the long-term quality and success of your DIY project.

FAQ

Q: What is the best type of blade for cutting vinyl plank flooring?

A: A carbide-tipped saw blade designed for laminate or vinyl plank flooring will deliver the best results. These blades are sharp and durable, minimizing chipping and splintering.

Q: How can I avoid chipping or splintering during cuts?

A: To avoid chipping, make sure your blade is sharp and cut with the grain of the vinyl planks. Using a cutting board to support the plank during cutting can also help.

Q: Can I use a jigsaw to cut vinyl plank flooring?

A: While a jigsaw can cut vinyl plank flooring, it’s not the ideal tool. Jigsaws are better suited for curved cuts, and their blade can cause excessive vibrations, increasing the risk of chipping or splintering.

Q: What is the best way to cut vinyl plank flooring around corners?

A: For cutting around corners, it’s best to use a miter saw or a special flooring cutter with an adjustable cutting depth.

Q: How do I know if my vinyl plank flooring is easy to cut?

A: The ease of cutting vinyl plank flooring depends on its core material. Some planks have a rigid core that requires special tools, while others have a flexible core that is easier to cut with a utility knife.

Best Tool To Use To Cut Vinyl Plank Flooring

https://youtube.com/watch?v=PVgTBxu03G0

Conclusion

Choosing the right tool to cut vinyl plank flooring is vital for a successful DIY project. From the simple utility knife to the powerful table saw, we’ve explored the options and their pros and cons. Consider your project size, your experience level, and the specific type of flooring you’re working with to make the best decision for you. We encourage you to practice on scrap pieces to get a feel for the tool and its cutting capabilities. This investment in the right tool and a little practice will save you time and frustration, ensuring a professional-looking finish that you can be proud of.

Are you planning a DIY vinyl plank flooring project? Share your thoughts and any questions you have in the comments section below!